May 7 and 11, 2002 Meeting Notes

In attendance:

John Carmack

Phil Eaton

Russ Blink

Neil Milburn

Joseph LaGrave (Saturday)

We expected to do more high speed rotor testing, but the new

tubing didn’t make it on time. We did

get another large solenoid, and Russ has made a new sensor circuit, so we are

basically ready to go as soon as we can re-plumb the rotor. We also changed the tank mounting on the

trailer so we can use it for both the horizontal test stand and the vertical

test stand without having to move it.

Big engine

The two 5.5” ID stainless engines from DynaTurn made it in,

and they turned out great. I originally

intended to make a copper sheet gasket for it, but we went ahead and tried it

without a gasket, and it seemed to seal fine just on its 20 bolts.

It turns out that we got perfect engine performance with only

60 silver screens in this engine, while we needed 70 in the 1” ID engines, so

there seems to be some beneficial scaling factors as work.

On Tuesday, we made several very smooth test firings, but

the performance was off a bit from what we expected. The throat was fabricated fairly sharp coming from the 45 degree

converging angle to the 15 degree diverging angle, so Russ took it home and

rounded it off a bit. This did increase

the throat area a bit, but our tests on Saturday showed both more thrust, and

higher Isp. In fact, the 122 Isp we

measured is the highest we have seen from any of our engines. We also had a kinked hose on Tuesday, so we

can’t for certain attribute the large performance boost to the smoothed throat,

but it is probably a good bet.

www.armadilloaerospace.com/may11_02/fivefive.xls

Chain Hoist Balance Test

We finally got around to hanging up Russ’s chain hoist, se

we can lift the vehicles from a single point to properly balance them.

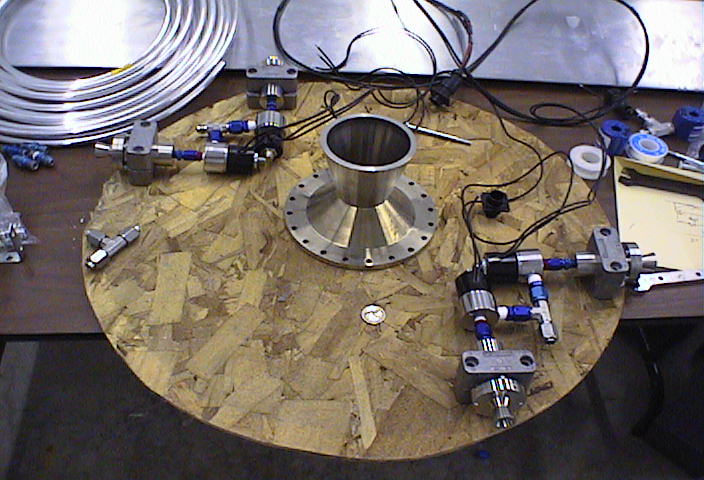

Attitude engine plate

The 2’ diameter vehicle will have offset side firing

engines, unlike all of our vehicles so far, which have had canted down firing

engines. We are using 1.25” tubing

clamps to mount the engines, and we were just barely able to rigidly connect

pairs of solenoids together with a T fitting, so we will only need to run two

hard lines on the bulkhead. We had to

remove the outer solenoid casings and grind a little off the retaining bolt,

but it was worth it for the compact plumbing arrangement.

The mounting bulkhead is just 3/8” playwood, but we sealed

it with epoxy to make it peroxide safe. The picture just shows them laid up on the press board that

stiffened the filament wound tubing for shipping, not our real bulkhead.

.

Cabin Hatch

We fitted internal retaining slides to the 2’ tube for our

lexan hatch. We had been planning on

making the hatch slide into a pocket on the bottom, and have a dog on the top,

but it turned out to be easy to just make sides on the top and bottom, and

slide the lexan to the side for getting in and out. We are just going to put two bolts through the lexan on the side,

with a strap between them on both the inside and outside. The bolts will also serve as slide

stops. This is not intended to be a

pressure tight cabin, just an aerodynamic fairing.

We should have left it alone after we had it all set up, but

we tried to heat form the lexan sheet so it wasn’t sprung so tightly into the

tube. A heat gun didn’t get it hot

enough to soften sufficiently, so we went after it with a torch for a

while. We got it curved a bit, but when

we tried to straighten out the edges a bit, we wound up making bit of a mess of

it. We are probably going to have the

plastics company that made our test stand shield curve another piece for us.

Upcoming Work

Full speed rotor testing

Replace

tubing

Water flow

the large solenoid for comparison

Test new

tach sensor

Attitude bulkhead testing

Finish

mounting and tube bending

Mount in

tube

Mount top

bulkhead with eye bolt in place of rotor hub

Make an

eight conductor CPC extension cable

Have Joseph

bring his Bobcat to suspend it outside

Big lander flights

Replace Ethernet

board in flight computer

Finish new

software architecture

Make new

mounting bracket for main engine

Precession attitude control tests

Add rotor

RPM control to flight computer

Get more

chain for tying down all four corners of the lander at the pad

Bore out one of the 1” engine nozzles from 0.33 to 0.45 to

see if we can use a larger throat to pack ratio

2” ID engines will be in next week

Regeneratively cooled chamber with

integral fuel injector

Tap

¼” NPT into the bottom of the spare NOS tank so we can run higher pressure

kerosene

Radiatiively cooled chamber

Fuel injector ring

Clamp ring for

non-bolted chamber

Fabricate

brass mockup and test with flood cooling

Get TZM to DynaTurn

Platinum

plate at Dallas Precious Metals

12” ID engine

Pay for

silver screens

Find

someone to roll the nozzle

Weld

everything together and cleanup

Fabricate

reinforced perforated metal retaining plate

High speed flight

Fabricate a sheet metal nose cone /

rotor spinner

Test new

parachute rocket system